MTMPVD GRAVIT

MTM Engineering

MTMPVD GRAVIT

MTM PVD Gravit is a special machine to coat glass and porcelain products. Using special sputter magnetron targets allows the machine to generate various colors which are impossible with other techniques. Direct current (DC), medium frequency (MF) and radio frequency (RF) options are available.

Product Gallery

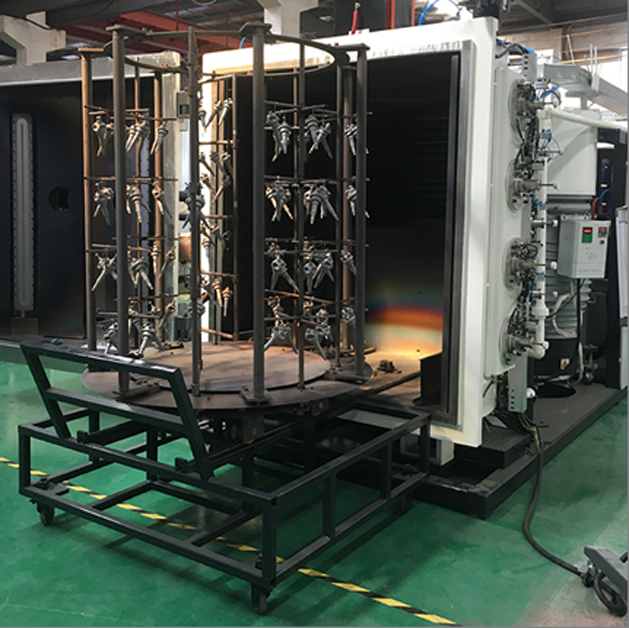

Vacuum Chamber

Inner Diameter 2000mm* Inner Height 2500mm, Vacuum chamber main body adopts 304 stainless steel, external reinforcing rib

adopts Q235; Vertical circular type, single front open door; On the door equipped with two inspection windows, can check the

inner working during deposition.

Multi arc ion costing system

Equipped with 18 sets of A100 type arc targets; Equipped with 18 sets of arc power supply, max. output current 200A;

Equipped with one set of 40KW pulse bias power supply; New machine will equipped with 18 titanium targets,

target size: φ100*40; Multi arc target holder and sealing adopt water cooling to protect them.

Vacuum pumping System

High vacuum pump: Two sets of KT-800 diffusion pump, (brand: Shenyang zhenlong), one set of valve.

Pumping Speed: 20000L/S, Power: 13KW/set; Equipped with two sets of cold trap; Use the electromagnetic heating,

with low electricity consumption and low failure rate.

Inner Diameter 2000mm* Inner Height 2500mm, Vacuum chamber main body adopts 304 stainless steel, external reinforcing rib

adopts Q235; Vertical circular type, single front open door; On the door equipped with two inspection windows, can check the

inner working during deposition.

Multi arc ion costing system

Equipped with 18 sets of A100 type arc targets; Equipped with 18 sets of arc power supply, max. output current 200A;

Equipped with one set of 40KW pulse bias power supply; New machine will equipped with 18 titanium targets,

target size: φ100*40; Multi arc target holder and sealing adopt water cooling to protect them.

Vacuum pumping System

High vacuum pump: Two sets of KT-800 diffusion pump, (brand: Shenyang zhenlong), one set of valve.

Pumping Speed: 20000L/S, Power: 13KW/set; Equipped with two sets of cold trap; Use the electromagnetic heating,

with low electricity consumption and low failure rate.

| Holding pump | One set of 2X-30 rotary vane pump, (brand: Chengdu Nanguang); Pumping Speed: 30L/S, Power: 3KW/set; |

|---|---|

| Total Power | Total Power about 195KW; Actual running power about 55KW/h. |

| Style/Type | Sports, Formal |

| Lining | 100% polyester taffeta with a DWR finish |

| Material | Lather, Cotton, Silk |

| Total Power | Total Power about 195KW; Actual running power about 55KW/h. |

| Cycle time | Around 40-50 minutes one cycle. (depends on the raw material). |

| Floor area | L8000mm*W4000mm*H3500 mm.. |

| Total water consumption | Water flow rate about: 8m3/h. |

| Total weight | About 11000kg |

| Electrical Control | It equipped with PLC and touch screen, will be easy to learn and operate. |